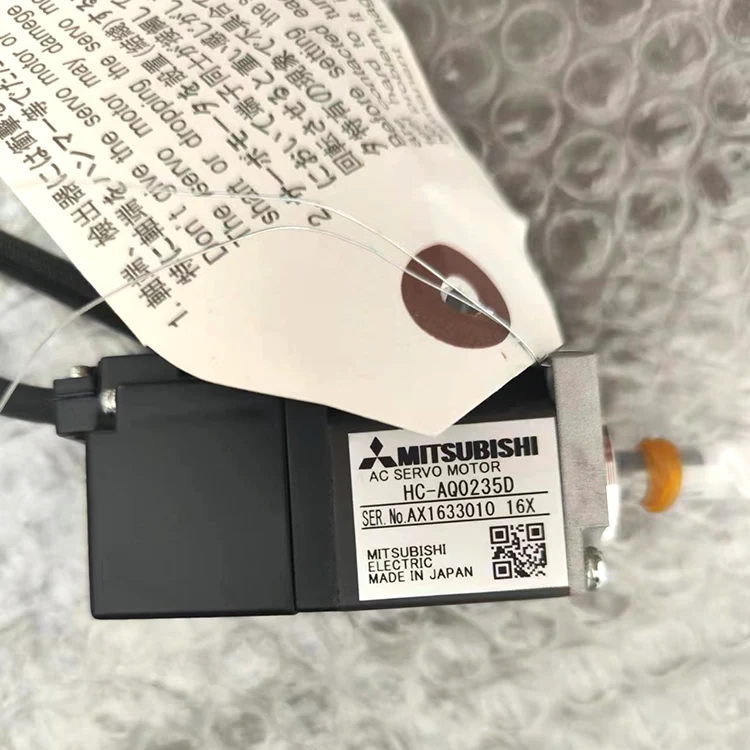

Optimize Your Automation with Mitsubishi HC-AQ0235D Servo Motor

In the world of industrial automation, precision and reliability are paramount. Among the many solutions available, the Mitsubishi Servo Motor HC-AQ0235D stands out for its exceptional performance and versatility. This article will delve into the features, applications, and common issues associated with this powerful servo motor, ensuring you have all the information needed to make an informed decision.

Features of Mitsubishi Servo Motor HC-AQ0235D

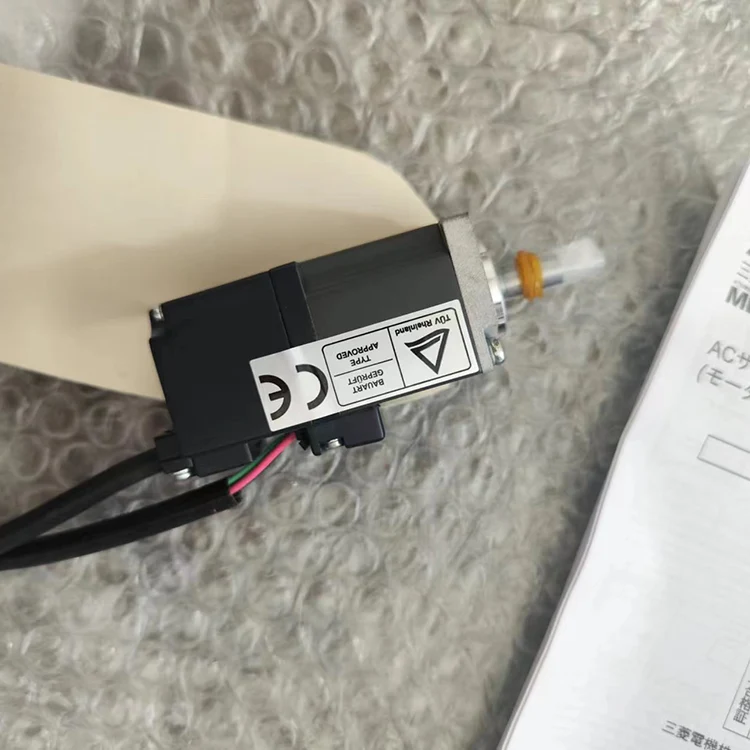

The Mitsubishi Servo Motor HC-AQ0235D is designed to deliver high torque and precision, making it an ideal choice for various industrial applications. Here are some key features:

- High Precision Control: With its advanced feedback system, the HC-AQ0235D offers precise positioning and speed control, essential for tasks requiring high accuracy.

- Robust Design: Built to withstand harsh industrial environments, this motor is both durable and reliable.

- Energy Efficiency: The HC-AQ0235D is engineered to optimize energy consumption, reducing operational costs without compromising performance.

- Compact Size: Despite its powerful capabilities, this servo motor has a compact design, making it suitable for installations where space is limited.

Applications of Mitsubishi HC-AQ0235D

The versatility of the Mitsubishi Servo Motor HC-AQ0235D allows it to be used in a wide range of applications, including:

- Robotics: Its high precision makes it perfect for robotic arms and automation systems.

- CNC Machines: Ideal for controlling the movements of CNC machines, ensuring accurate and smooth operation.

- Packaging Machinery: Used in packaging equipment for precise control over the packaging process.

- Conveyor Systems: Ensures efficient and precise movement in conveyor belts and automated material handling systems.

Common Issues and Solutions

While the Mitsubishi Servo Motor HC-AQ0235D is known for its reliability, users may encounter some common issues during operation. Understanding these problems and their solutions can help maintain optimal performance.

Overheating

Issue: Prolonged use or insufficient cooling can cause the motor to overheat.

Solution: Ensure proper ventilation and cooling systems are in place. Regularly check and maintain these systems to prevent overheating.

Vibration and Noise

Issue: Excessive vibration and noise may occur if the motor is not mounted correctly.

Solution: Verify that the motor is securely mounted and aligned. Use vibration dampening mounts if necessary.

Encoder Errors

Issue: Errors in the feedback system can lead to incorrect positioning.

Solution: Regularly inspect and clean the encoder. Ensure it is correctly calibrated and replace it if it shows signs of wear.

Overloading

Issue: Operating the motor beyond its rated capacity can lead to damage and reduced lifespan.

Solution: Always operate within the specified load limits. Use a motor with a higher capacity if the application demands more power.

Conclusion

The Mitsubishi Servo Motor HC-AQ0235D is a versatile and reliable choice for various industrial applications. Its high precision, robust design, and energy efficiency make it a valuable asset in automation and control systems. By understanding its features, applications, and potential issues, users can maximize the benefits and longevity of this servo motor.

For more information and to explore our range of Mitsubishi servo motors, visit our Mitsubishi Servo System. Discover how these advanced solutions can enhance your automation projects and drive efficiency in your operations.

By following these guidelines and utilizing the Mitsubishi Servo Motor HC-AQ0235D effectively, you can achieve superior performance and reliability in your industrial applications.

Ples click the Live Chat ↘button on the lower right corner to talk to us.

Or send us Quick Contact ↓ message at the bottom of the page.