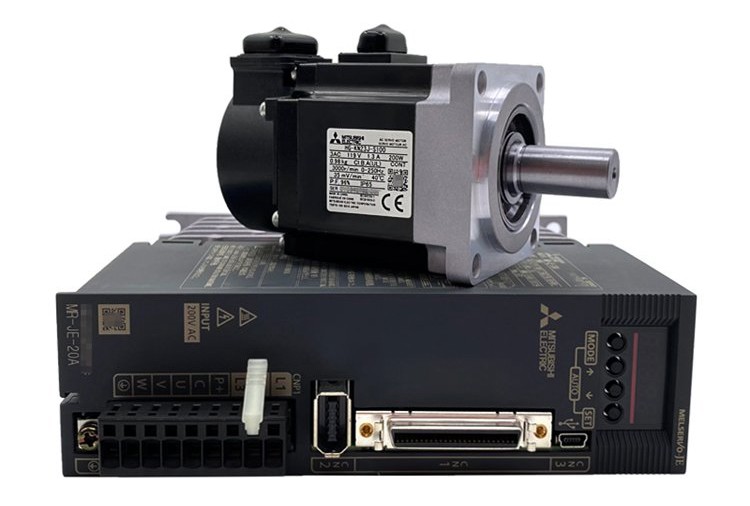

Mitsubishi Servo Motor HJ-KS-J Series

Mitsubishi servo motor HJ-KS series:

HJ-KS13J, HJ-KS13BJ

HJ-KS23J, HJ-KS23BJ

HJ-KS43J, HJ-KS43BJ

HJ-KS73J, HJ-KS73BJ

HJ-KS102J, HJ-KS102BJ

HJ-KS152J, HJ-KS152BJ

HJ-KS202J, HJ-KS202BJ

HJ-KS13J motor

Rated output: 0.1KW

Rated speed: 3000r/min

Maximum torque: 0.95N · m

Features: Suitable for application scenarios that require high-precision control and fast response, such as packaging machinery. The HJ-KS13J motor has USB and RS-422 serial communication functions, which facilitate parameter setting, trial operation, status display monitoring, and gain adjustment operations.

HJ-KS23J motor

Rated output: higher than HJ-KS13J, specific value not provided

Application scenario: May be suitable for mechanical systems that require higher torque and power output, such as certain links in automated production lines.

HJ-KS43J, HJ-KS73J, HJ-KS102J motors:

Rated output: As the model number increases, the rated output also gradually increases, suitable for different load and power demand application scenarios.

Usage characteristics: This series of motors usually have a low inertia design, suitable for high-speed and high-frequency operation needs, while providing high-precision positioning and smooth rotation.

HJ-KS152J motor:

Rated output: 1.5KW

Rated speed: 2000r/min

Features: As a high-power motor in the HJ-KS series, the HJ-KS152J motor may be used in applications that require high torque and high power output, such as heavy-duty machinery or high load production lines.

HJ-KS202J motor:

Rated output: No specific value given, but expected to be higher than HJ-KS152J

Application scenario: Similar to HJ-KS152J, HJ-KS202J motors may be used in applications that require higher power and torque output, such as large equipment or heavy-duty production lines.

Mitsubishi servo motor HG-KR series:

HG-KR13, HG-KR13B, HG-KR13K, HG-KR13J, HG-KR13BJ

HG-KR23, HG-KR23B, HG-KR23K, HG-KR23J, HG-KR23BJ

HG-KR43, HG-KR43B, HG-KR43K, HG-43BK, HG-KR43J, HG-KR43BJ

HG-KR73, HG-KR73B, HG-KR73K, HG-73BK, HG-KR73J, HG-KR73BJ

Mitsubishi servo motor HG-KN series:

HG-KN13J-S100, HG-KN13BJ-S100

HG-KN23J-S100, HG-KN23BJ-S100

HG-KNJ-S100, HG-KN43BJ-S100

HG-KN52J-S100, HG-KN52BJ-S100

HG-KN73J-S100, HG-KN73BJ-S100

HG-KN102J-S100, HG-KN102BJ-S100

HG-KN152J-S100, HG-KN152BJ-S100

HG-KN202J-S100, HG-KN202BJ-S100

Mitsubishi servo motor HG-SN series:

HG-SN52J-S100, HG-SN52BJ-S100

HG-SN102J-S100, HG-SN102BJ-S100

HG-SN152J-S100, HG-SN152BJ-S100

HG-SN202J-S100, HG-SN202BJ-S100

HG-SN302J-S100, HG-SN302BJ-S100

Possible Issues, Preventive Measures, and Maintenance Methods for HJ-KS-J Series Motors

I. Possible Issues During Operation

Overheating:

Prolonged high-load operation or inadequate heat dissipation can cause motor overheating, affecting performance and lifespan.

Solution: Regularly inspect the motor’s cooling system to ensure the fan is functioning correctly and the heat sinks are unobstructed. Avoid prolonged overload operation.

Vibration and Noise:

Unstable installation, damaged bearings, or unbalanced loads can lead to increased vibration and noise.

Solution: Ensure the motor is securely mounted. Regularly check bearing conditions and replace damaged bearings promptly. Maintain load balance to prevent overload operation.

Reduced Insulation Resistance:

Prolonged operation or humid environments can decrease insulation resistance, increasing the risk of motor breakdown.

Solution: Use an insulation tester to periodically measure the motor’s insulation resistance and compare it to standard values. If insulation resistance falls below standards, promptly perform drying treatment.

Loose Wiring Connections:

Loose wiring can cause poor contact, phase loss, and other issues, impacting motor performance.

Solution: Regularly inspect motor wiring to ensure connections are tight and reliable. Tighten loose connections promptly to prevent malfunctions.

II. Preventive Measures

Regular Maintenance:

Establish a detailed motor maintenance schedule including regular inspections, cleaning, and lubrication. Ensure the motor operates in optimal condition.

Proper Operation:

Operators should receive professional training to understand motor usage and maintenance. Follow operation manual guidelines to avoid overload and frequent start-stops.

Environmental Control:

Maintain a dry, clean work environment for the motor, avoiding dust, moisture, and chemical accumulation. Ensure proper ventilation and cooling system function.

Use High-Quality Components:

When purchasing or replacing motor components, select reputable brands and reliable suppliers. Ensure components meet specifications and standards to enhance motor stability and safety.

Servo motor and servo drive coordination:

| Series | Power | Servo Motor | Servo Amplifier |

| HG-KS Series (Small power) |

100w | HJ-KS13J/HJ-KS13BJ | MR-JE-10AS |

| 200w | HJ-KS23J/HJ-KS23BJ | MR-JE-20AS | |

| 400w | HJ-KS43J/HJ-KS43BJ | MR-JE-40AS | |

| 750w | HJ-KS73J/HJ-KS73BJ | MR-JE-70AS | |

| HG-KS Series (Large power) |

1kw | HJ-KS102J/HJ-KS102BJ | MR-JE-100AS |

| 1.5kw | HJ-KS152J/HJ-KS152BJ | MR-JE-200AS | |

| 2kw | HJ-KS202J/HJ-KS202BJ | MR-JE-200AS |

| Series | Power | Servo Motor | Servo Amplifier |

| HG-KR Series (Low inertia, small power, rated speed 3000rpm) |

100w | HG-KR13(B)J | MR-J4-10A |

| 200w | HG-KR23(B)J | MR-J4-20A | |

| 400w | HG-KR43(B)J | MR-J4-40A | |

| 750w | HG-KR73(B)J | MR-J4-70A | |

| HG-SR Series (Medium inertia, medium power, rated speed 2000rpm) |

500w | HG-SR52(B)J | MR-J4-70A |

| 1kw | HG-SR102(B)J | MR-J4-100A | |

| 1.5kw | HG-SR152(B)J | MR-J4-200A | |

| 2kw | HG-SR202(B)J | MR-J4-200A | |

| 3.5kw | HG-SR352(B)J | MR-J4-350A | |

| 5kw | HG-SR502(B)J | MR-J4-500A | |

| 7kw | HG-SR702(B)J | MR-J4-700A |

| Series | Power | Servo Motor | Servo Amplifier |

| HG-KN Series (Low inertia, low capacity) |

100w | HG-KN13(B)J-S100 | MR-JE-10A / MR-JE-10B / MR-JE-10C |

| 200w | HG-KN23(B)J-S100 | MR-JE-20A / MR-JE-20B / MR-JE-20C | |

| 400w | HG-KN43(B)J-S100 | MR-JE-40A / MR-JE-40B / MR-JE-40C | |

| 750w | HG-KN73(B)J-S100 | MR-JE-70A / MR-JE-70B / MR-JE-70C | |

| HG-SN Series (Medium inertia, medium capacity) |

0.5kw | HG-SN52(B)J-S100 | MR-JE-70A / MR-JE-70B / MR-JE-70C |

| 1kw | HG-SN102(B)J-S100 | MR-JE-100A / MR-JE-100B / MR-JE-100C | |

| 1.5kw | HG-SN152(B)J-S100 | MR-JE-200A / MR-JE-200B / MR-JE-200C | |

| 2kw | HG-SN202(B)J-S100 | MR-JE-200A / MR-JE-200B / MR-JE-200C | |

| 3kw | HG-SN302(B)J-S100 | MR-JE-300A / MR-JE-300B / MR-JE-300C |

III. Maintenance Methods

Cleaning and Maintenance:

Regularly clean the motor casing and heat sinks to remove dust and dirt. Check fan operation to ensure efficient heat dissipation.

Insulation Resistance Check:

Periodically measure the motor’s insulation resistance with an insulation tester and compare to standard values. Address reduced insulation resistance promptly with drying treatment.

Tightening Wiring Connections:

Regularly inspect motor wiring to ensure connections are secure. Tighten loose connections to prevent malfunctions.

Bearing Replacement:

Periodically check bearing condition. Replace damaged or poorly lubricated bearings with new ones and apply appropriate amounts of lubricant.

Maintenance Record Keeping:

Maintain detailed maintenance records, including the time, content, issues found, and resolutions. This facilitates tracking maintenance history and identifying potential issues early.

By implementing these measures, potential issues with HJ-KS-J series motors can be effectively prevented, extending their lifespan. In the event of issues, prompt identification and corresponding maintenance measures ensure continuous and stable motor operation.

Advanced one click tuning: No need for a computer, one click operation can complete servo adjustment. In addition, it can automatically adjust vibration to resist robust filters

High resolution encoder: equipped with 131072PULSES/REV (17BIT) incremental encoder, achieving high-precision equipment.

Increased transient stop tolerance: Equipped with transient stop TOUGH DRIVE function and large main circuit capacitors, reducing shutdown losses caused by transient stops.

Reduce maintenance procedures: Store servo data before and after alarms in ROM memory to quickly and accurately identify the cause of the alarm.

Reliable performance: Utilizing a dedicated engine to achieve a speed frequency response of 2.0KHZ and shorten the interval time.

Contact:

Feel free to contact us!

Skype/Wechat: WOOLARS

Email: alec@wooalrs.com

Click the Live Chat ↘button on the lower right corner to talk to us.

Or Click>>>Leave message